10+ Ptfe Membrane Tips For Improved Gas Flow

PTFE (Polytetrafluoroethylene) membranes are widely used in various industrial applications, including gas flow systems, due to their unique properties such as high chemical resistance, low friction, and excellent durability. However, to achieve improved gas flow and maximize the benefits of PTFE membranes, it is essential to consider several factors and implement specific tips. In this article, we will delve into 10+ tips for enhanced gas flow using PTFE membranes, exploring the technical aspects, application considerations, and maintenance strategies.

Understanding PTFE Membranes

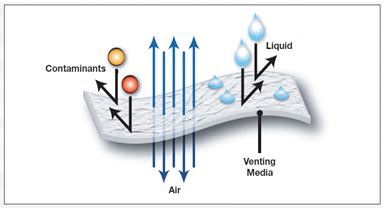

Before diving into the tips for improved gas flow, it is crucial to understand the characteristics of PTFE membranes. PTFE is known for its non-reactive nature, making it an ideal material for applications involving corrosive or sensitive gases. The hydrophobic nature of PTFE also contributes to its effectiveness in gas flow systems, as it prevents water and other liquids from penetrating the membrane. Understanding these properties is key to optimizing gas flow and selecting the appropriate PTFE membrane for specific applications.

Tip 1: Selecting the Right Pore Size

The pore size of the PTFE membrane significantly affects gas flow. Larger pore sizes can lead to increased flow rates but may compromise the membrane’s ability to filter out particles and contaminants. Conversely, smaller pore sizes offer better filtration but can restrict gas flow. It is essential to balance these factors based on the specific requirements of the application. For instance, in applications where high purity of the gas is critical, smaller pore sizes might be preferred, even if it means a slight reduction in gas flow rate.

| Pore Size | Flow Rate | Filtration Efficiency |

|---|---|---|

| 0.1 μm | Low | High |

| 0.5 μm | Medium | Medium |

| 1.0 μm | High | Low |

Tip 2: Membrane Thickness and Gas Flow

The thickness of the PTFE membrane also plays a significant role in gas flow. Thicker membranes can offer greater durability and resistance to pressure but may reduce gas flow rates due to increased resistance. Thinner membranes, on the other hand, can enhance gas flow but might be more prone to damage. The ideal thickness depends on the balance between durability and flow rate requirements.

Tip 3: Surface Treatment for Enhanced Flow

Applying a surface treatment to the PTFE membrane can significantly improve gas flow. Treatments that reduce the membrane’s surface energy can make it more hydrophobic, potentially increasing the flow rate of gases. However, the choice of surface treatment must be carefully considered to ensure compatibility with the gases being used and to avoid compromising the membrane’s integrity.

Tip 4: Operating Conditions and Gas Flow

Operating conditions such as temperature and pressure can substantially affect gas flow through PTFE membranes. Higher temperatures can increase the flow rate by reducing the viscosity of the gas, but excessive heat can degrade the PTFE material. Similarly, increased pressure can force more gas through the membrane but risks damaging it if the pressure exceeds the membrane’s limit.

Tip 5: Membrane Cleaning and Maintenance

Regular cleaning and maintenance of PTFE membranes are crucial for sustained gas flow. Contaminants and particles can clog the pores and drastically reduce flow rates. Cleaning methods should be gentle to avoid damaging the membrane, and the frequency of cleaning depends on the application and the level of contamination.

Tip 6: Gas Composition and Compatibility

The composition of the gas is another critical factor. PTFE membranes are compatible with a wide range of gases due to their non-reactive nature. However, corrosive gases can still affect the membrane’s performance over time, and moisture can compromise the hydrophobic properties of the PTFE. Ensuring the gas is dry and free of corrosive components is essential for optimal performance.

Tip 7: System Design Considerations

The design of the gas flow system itself can significantly impact the performance of the PTFE membrane. Turbulent flow should be minimized to prevent membrane damage, and dead spaces where gas can stagnate should be avoided. A well-designed system can help maintain consistent flow rates and prolong the life of the membrane.

Tip 8: Monitoring and Replacement

Regular monitoring of the gas flow rate and pressure drop across the membrane can indicate when the membrane needs cleaning or replacement. Decreased flow rates or increased pressure drops are signs that the membrane’s pores may be clogged or that the membrane is deteriorating.

Tip 9: Material Quality and Certification

The quality of the PTFE material used for the membrane is vital. Certified materials that meet specific standards for purity, thickness, and pore size ensure consistency and reliability in gas flow applications. Using high-quality materials can minimize variations in performance and extend the lifespan of the membrane.

Tip 10: Customization for Specific Applications

Finally, considering customization options for PTFE membranes can be beneficial for unique or demanding applications. Custom pore sizes, thicknesses, and surface treatments can be tailored to meet specific requirements, potentially leading to significant improvements in gas flow and overall system performance.

What is the typical lifespan of a PTFE membrane in gas flow applications?

+The lifespan of a PTFE membrane can vary widely depending on the application, operating conditions, and maintenance. Generally, with proper care and use, PTFE membranes can last from several months to several years.

How often should PTFE membranes be cleaned in gas flow systems?

+The cleaning frequency depends on the level of contamination and the specific application. Regular monitoring of flow rates and pressure drops can help determine when cleaning is necessary. As a general rule, membranes should be cleaned at the first sign of decreased performance.

In conclusion, optimizing gas flow through PTFE membranes requires careful consideration of several factors, including pore size, membrane thickness, surface treatment, operating conditions, and maintenance. By following these 10+ tips and understanding the unique properties and applications of PTFE membranes, users can enhance gas flow, improve system efficiency, and prolong the lifespan of the membrane. Whether in industrial processes, laboratory settings, or other applications, the right approach to using PTFE membranes can make a significant difference in performance and reliability.