12 Bending Deformation Failure Fixes

The issue of bending deformation failure is a critical concern in various engineering fields, including mechanical, aerospace, and civil engineering. Bending deformation occurs when a material or structure is subjected to external forces that cause it to bend or deform, potentially leading to failure. In this article, we will delve into the world of bending deformation failure fixes, exploring 12 key strategies for mitigating or preventing this type of failure.

Understanding Bending Deformation Failure

Bending deformation failure can occur due to a variety of factors, including material defects, design flaws, and external loading conditions. When a material or structure is subjected to bending forces, it can experience elastic deformation, which is a temporary and reversible change in shape. However, if the bending forces exceed the material’s yield strength, the material can undergo plastic deformation, leading to permanent damage and potentially catastrophic failure.

Causes of Bending Deformation Failure

Some common causes of bending deformation failure include:

- Insufficient material strength or stiffness

- Poor design or manufacturing techniques

- Excessive loading conditions, such as weight or pressure

- Corrosion or wear and tear over time

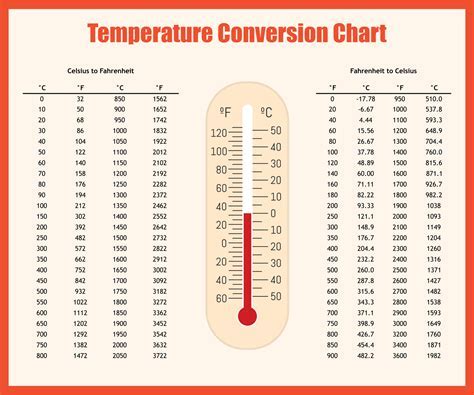

- Thermal stresses or temperature fluctuations

12 Bending Deformation Failure Fixes

To mitigate or prevent bending deformation failure, engineers and designers can employ a range of strategies. Here are 12 key fixes:

- Material selection: Choosing materials with high strength-to-weight ratios, such as composites or high-strength alloys, can help reduce the risk of bending deformation failure.

- Design optimization: Using computer-aided design (CAD) software and finite element analysis (FEA) to optimize the design of a structure or component can help minimize bending stresses and reduce the risk of failure.

- Reinforcement: Adding reinforcing materials, such as fibers or particles, to a material can help increase its strength and stiffness, reducing the risk of bending deformation failure.

- Support structures: Adding support structures, such as beams or columns, can help distribute loads and reduce bending stresses, minimizing the risk of failure.

- Load reduction: Reducing the external loads applied to a structure or component can help minimize bending stresses and reduce the risk of failure.

- Shape optimization: Optimizing the shape of a structure or component can help reduce bending stresses and minimize the risk of failure.

- Surface treatment: Applying surface treatments, such as coatings or platings, can help improve the strength and durability of a material, reducing the risk of bending deformation failure.

- Inspection and maintenance: Regular inspection and maintenance can help identify potential issues before they lead to bending deformation failure.

- Material processing: Using advanced material processing techniques, such as 3D printing or forging, can help create materials with optimized properties and reduced risk of bending deformation failure.

- Hybrid materials: Using hybrid materials that combine different materials with unique properties can help create structures or components with improved strength and stiffness, reducing the risk of bending deformation failure.

- Smart materials: Using smart materials that can respond to changing conditions, such as shape-memory alloys or piezoelectric materials, can help create adaptive structures or components that can mitigate bending deformation failure.

- Advanced analysis techniques: Using advanced analysis techniques, such as machine learning or artificial intelligence, can help predict and prevent bending deformation failure by identifying potential issues before they occur.

Case Studies and Examples

Several case studies and examples demonstrate the effectiveness of these bending deformation failure fixes. For instance, the use of composite materials in the aerospace industry has helped reduce the risk of bending deformation failure in aircraft structures. Similarly, the application of surface treatments has improved the durability and strength of materials in the automotive industry.

| Material | Strength-to-Weight Ratio | Applications |

|---|---|---|

| Carbon fiber composite | High | Aerospace, automotive, sports equipment |

| High-strength alloy steel | Medium | Construction, machinery, industrial equipment |

| Shape-memory alloy | Low | Medical devices, aerospace, automotive |

What is the most common cause of bending deformation failure?

+The most common cause of bending deformation failure is insufficient material strength or stiffness. This can be due to a variety of factors, including material defects, design flaws, or external loading conditions.

How can I prevent bending deformation failure in my design?

+To prevent bending deformation failure, you can use a range of strategies, including material selection, design optimization, reinforcement, and load reduction. It’s also important to consider the external loading conditions and ensure that your design can withstand a range of stresses and strains.

What are some common materials used to reduce bending deformation failure?

+Some common materials used to reduce bending deformation failure include composite materials, high-strength alloys, and shape-memory alloys. These materials offer improved strength, stiffness, and durability, making them well-suited for applications where bending deformation failure is a concern.