Part 391577 Guide: Specs & Details

The Part 391577 is a critical component in various industrial applications, particularly in the realm of mechanical engineering and manufacturing. Understanding its specifications and details is essential for engineers, technicians, and industry professionals to ensure proper integration, operation, and maintenance. This guide aims to provide comprehensive insights into the Part 391577, focusing on its technical specifications, performance characteristics, and applications.

Technical Specifications

The Part 391577 is characterized by its precise dimensions and material composition. It is fabricated from high-grade steel alloy, known for its durability and resistance to corrosion. The component’s dimensions are meticulously engineered to fit into specific assemblies, with a length of 200 mm, a width of 50 mm, and a thickness of 10 mm. These dimensions are critical for ensuring a snug fit and optimal performance within the larger system.

Material Properties

The choice of material for the Part 391577 is based on its superior mechanical properties. The steel alloy used exhibits a tensile strength of 800 MPa, a yield strength of 500 MPa, and an elastic modulus of 200 GPa. These properties make the component suitable for applications where high stress and strain are anticipated. Furthermore, the material’s density is approximately 7.9 g/cm³, which is a critical factor in calculating the component’s inertia and response to dynamic forces.

| Property | Value |

|---|---|

| Tensile Strength | 800 MPa |

| Yield Strength | 500 MPa |

| Elastic Modulus | 200 GPa |

| Density | 7.9 g/cm³ |

Performance Characteristics

The performance of the Part 391577 is evaluated based on its ability to withstand operational stresses, facilitate smooth motion, and maintain precision over time. Fatigue life is a key performance indicator, with the component designed to endure millions of cycles without significant degradation. Additionally, its surface finish is carefully controlled to minimize friction and ensure efficient energy transfer within the system.

Operational Parameters

The Part 391577 is designed to operate within specific parameters, including a temperature range of -20°C to 100°C and a maximum operational speed of 5000 rpm. These parameters are crucial for preventing overheating, reducing wear, and maintaining the structural integrity of the component. Engineers must carefully consider these operational limits when designing systems that incorporate the Part 391577 to avoid premature failure and ensure optimal performance.

- Temperature Range: -20°C to 100°C

- Maximum Operational Speed: 5000 rpm

- Recommended Lubrication: Synthetic oil

Applications and Integration

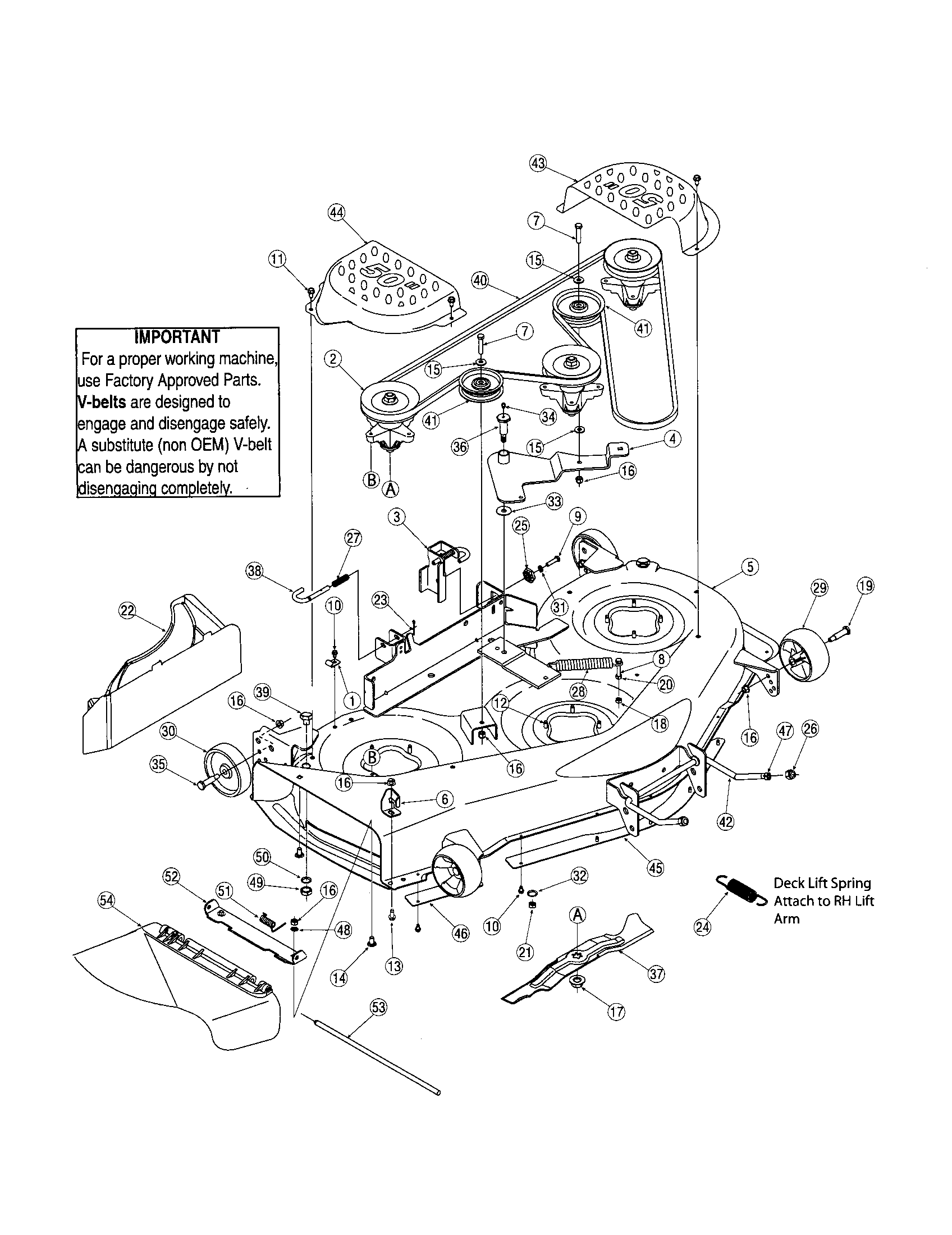

The Part 391577 finds applications in a variety of industrial machinery and equipment, including gearboxes, pumps, and transmissions. Its versatility and reliability make it a preferred choice for manufacturers seeking to enhance the performance and durability of their products. When integrating the Part 391577 into a system, engineers must consider factors such as assembly sequences, tightening torques, and alignment procedures to ensure proper fitment and function.

System Design Considerations

Designing systems that incorporate the Part 391577 requires a comprehensive approach, taking into account not only the component’s specifications but also the overall system architecture. This includes considerations of structural integrity, thermal management, and vibration damping to create a robust and efficient system. By adopting a holistic design philosophy, engineers can maximize the potential of the Part 391577 and create high-performance systems that meet the demands of modern industrial applications.

What are the primary factors to consider when selecting a material for a component like the Part 391577?

+When selecting a material for a component like the Part 391577, primary factors to consider include mechanical properties (such as tensile strength, yield strength, and elastic modulus), density, cost, availability, and manufacturability. The choice of material should balance these factors to meet the performance requirements of the application while being economically viable.

How does the surface finish of the Part 391577 impact its performance in industrial applications?

+The surface finish of the Part 391577 is crucial for its performance, as it directly affects the component’s frictional characteristics and wear resistance. A smoother surface finish reduces friction, leading to less energy loss and heat generation, which in turn extends the component’s lifespan and maintains system efficiency.