Steam Generator Corrosion

Steam generator corrosion is a critical issue in the power generation industry, particularly in nuclear and fossil fuel-based power plants. The steam generator, also known as a boiler, is a vital component of the power plant, responsible for converting the heat energy from the fuel into steam, which then drives the turbine to produce electricity. However, the steam generator is susceptible to corrosion, which can lead to reduced efficiency, increased maintenance costs, and even premature failure. In this article, we will delve into the causes, effects, and prevention strategies of steam generator corrosion.

Causes of Steam Generator Corrosion

Steam generator corrosion can occur due to various factors, including water chemistry, material selection, and operational conditions. The water chemistry plays a crucial role in determining the corrosion rate, as the presence of impurities such as oxygen, chloride, and sulfate can accelerate corrosion. The material selection is also important, as some materials are more resistant to corrosion than others. For example, stainless steel is more resistant to corrosion than carbon steel. Operational conditions, such as temperature, pressure, and flow rate, can also impact corrosion rates.

Types of Corrosion

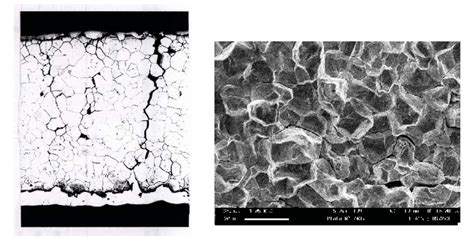

There are several types of corrosion that can occur in steam generators, including pitting corrosion, crevice corrosion, and stress corrosion cracking. Pitting corrosion occurs when a localized area of the metal surface is exposed to a corrosive environment, resulting in the formation of a pit. Crevice corrosion occurs when a crevice or gap between two metal surfaces is exposed to a corrosive environment, resulting in corrosion of the metal. Stress corrosion cracking occurs when a metal is subjected to tensile stress and a corrosive environment, resulting in the formation of cracks.

| Corrosion Type | Description | Causes |

|---|---|---|

| Pitting Corrosion | Localized corrosion resulting in pit formation | Impurities in water, high temperature, and low pH |

| Crevice Corrosion | Corrosion occurring in crevices or gaps between metal surfaces | Stagnant water, high chloride levels, and low oxygen levels |

| Stress Corrosion Cracking | Cracking of metal due to tensile stress and corrosive environment | High temperature, high pressure, and corrosive water chemistry |

Effects of Steam Generator Corrosion

Steam generator corrosion can have significant effects on the power plant’s operation, including reduced efficiency, increased maintenance costs, and premature failure. Corrosion can lead to the formation of deposits, which can reduce the heat transfer efficiency of the steam generator, resulting in reduced power output. Additionally, corrosion can require costly repairs and replacement of damaged components, leading to increased maintenance costs. In severe cases, corrosion can lead to premature failure of the steam generator, resulting in extended downtime and lost revenue.

Consequences of Corrosion

The consequences of steam generator corrosion can be severe, including economic losses, environmental impacts, and safety risks. Economic losses can result from reduced power output, increased maintenance costs, and premature failure of the steam generator. Environmental impacts can result from the release of corrosive substances into the environment, which can harm aquatic life and contaminate soil and water. Safety risks can result from the potential for equipment failure, which can lead to injuries and fatalities.

- Economic losses: Reduced power output, increased maintenance costs, and premature failure of the steam generator

- Environmental impacts: Release of corrosive substances into the environment, harm to aquatic life, and contamination of soil and water

- Safety risks: Potential for equipment failure, injuries, and fatalities

What are the primary causes of steam generator corrosion?

+The primary causes of steam generator corrosion include water chemistry, material selection, and operational conditions. Impurities in the water, such as oxygen, chloride, and sulfate, can accelerate corrosion, while the selection of corrosion-resistant materials and effective maintenance strategies can help mitigate corrosion risks.

What are the effects of steam generator corrosion on power plant operation?

+Steam generator corrosion can have significant effects on power plant operation, including reduced efficiency, increased maintenance costs, and premature failure. Corrosion can lead to the formation of deposits, which can reduce the heat transfer efficiency of the steam generator, resulting in reduced power output. Additionally, corrosion can require costly repairs and replacement of damaged components, leading to increased maintenance costs.

In conclusion, steam generator corrosion is a critical issue in the power generation industry, requiring careful attention to water chemistry, material selection, and operational conditions. By understanding the causes, effects, and prevention strategies of steam generator corrosion, power plant operators can take proactive steps to mitigate corrosion risks and ensure the safe and efficient operation of their facilities.